Types of Finishes - Stainless Steel Council Session 3

One of the aesthetic aspects of stainless steel is its "shiny" factor. If you're easily distracted by shiny things, this might be a good time for you to ask someone else to read this blog to you.

One of the aesthetic aspects of stainless steel is its "shiny" factor. If you're easily distracted by shiny things, this might be a good time for you to ask someone else to read this blog to you.

For sheet type stainless steel at least 3/16" thick and at least 24" wide the Stainless Steel Information Center has a great overview of the type of finishes. From our experience with stainless steel, the most common in commercial settings is Bright Annealed (BA or 2BA), No 3, No 4. Finish No. 7 and 8 are also available in commercial settings but these finishes are more used in residential settings.

A Bright Annealed finish

is produced by heat-treating (annealing) in a controlled atmosphere furnace. It has a mirror like appearance but may have some cloudiness and other imperfections. Bright annealed stainless is sometimes buffed to attain a more mirror-like finish. It is often specified for applications where a highly reflective surface is desired." Your high grade, aesthetic stainless steel might be this type.

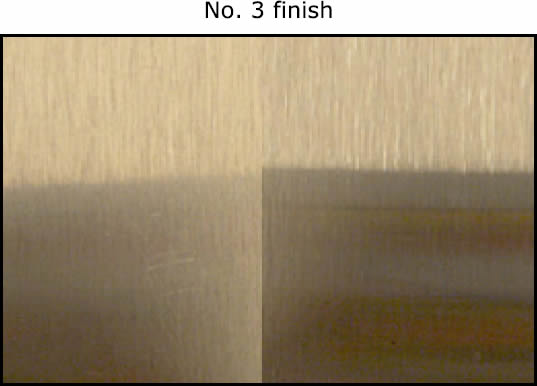

A No. 3 finish

is characterized by short, relatively coarse, parallel polishing lines, which extend uniformly along the length of the coil. It is obtained by either mechanically polishing with gradually finer abrasives or by passing the coil through special rolls, which press a pattern into the surface that simulates the appearance of mechanical abrasion. It is a moderately reflective finish." This finish is mainly used for kitchen equipment and food processing equipment.

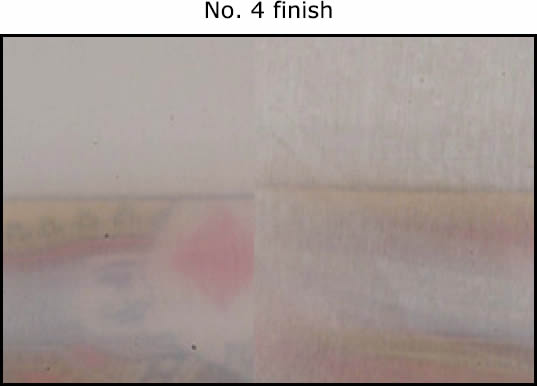

A No. 4 finish

is characterized by short, parallel polishing lines, which extend uniformly along the length of the coil. It is obtained by mechanically polishing a No. 3 finish with gradually finer abrasives. Depending on the requirements of the application, the final finish can be anywhere between 120 and 320 grit." This finish is used for numerous applications as it is easy to produce and works well in fabrication. Prima-Restaurant-Equipment's commercial

stainless steel tables, commerical

stainless steel sinks and other stainless steel

products are the No. 4 finish. They are characterized by parallel polishing

lines and are fairly reflective. This is a good finish for commercial use as it

helps hide scratches and imperfections caused in a kitchen or commercial

environment.

Prima-Restaurant-Equipment's commercial

stainless steel tables, commerical

stainless steel sinks and other stainless steel

products are the No. 4 finish. They are characterized by parallel polishing

lines and are fairly reflective. This is a good finish for commercial use as it

helps hide scratches and imperfections caused in a kitchen or commercial

environment.