Grease Trap 101: Types

The first is the Hydromechanical. These units rely

on the principles of heat and gravity to separate the FOG from the waste water.

Normally these units are carbon steel or plastic. Hydromechanical grease traps

control the flow of water allowing the hot water to cool. The baffle catches

the FOG and keeps it inside the grease trap. These grease traps must be cleaned

manually and often. The sizing of the Hydromechanical units are expressed in

poundage and in gallons per minute (GPM) flow. Sizes are normally 8lb/4GPM,

20lb/10GPM, 30lb/15GPM, 40lb/20GPM, 50lb/25GPM, 70lb/35GPM and 100lb/50GPM

units.

The first is the Hydromechanical. These units rely

on the principles of heat and gravity to separate the FOG from the waste water.

Normally these units are carbon steel or plastic. Hydromechanical grease traps

control the flow of water allowing the hot water to cool. The baffle catches

the FOG and keeps it inside the grease trap. These grease traps must be cleaned

manually and often. The sizing of the Hydromechanical units are expressed in

poundage and in gallons per minute (GPM) flow. Sizes are normally 8lb/4GPM,

20lb/10GPM, 30lb/15GPM, 40lb/20GPM, 50lb/25GPM, 70lb/35GPM and 100lb/50GPM

units.

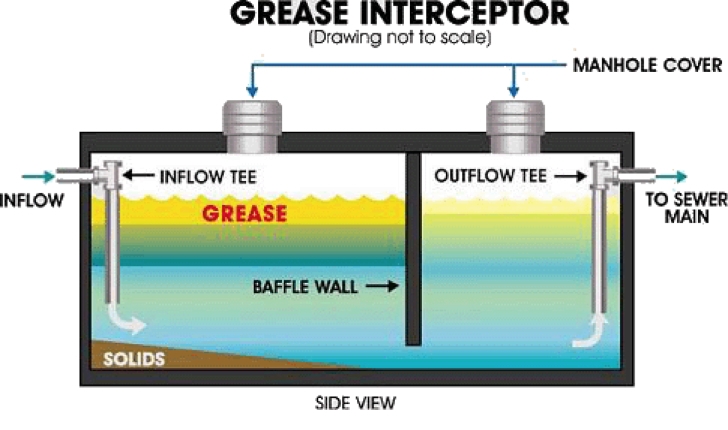

The second type of grease trap is Gravity. This type of grease

trap uses compartments of two or more and uses the larger amount of water

flowing to slow down the water inside the trap. This allows for FOG to become

buoyant and to separate. The physical size of Gravity grease traps compared to

the Hydromechanical is large. These grease traps are more efficient, allowing

90% of the FOG to be collected out of the water. The sizing of the Gravity

units are expressed in the gallons it will hold.

The second type of grease trap is Gravity. This type of grease

trap uses compartments of two or more and uses the larger amount of water

flowing to slow down the water inside the trap. This allows for FOG to become

buoyant and to separate. The physical size of Gravity grease traps compared to

the Hydromechanical is large. These grease traps are more efficient, allowing

90% of the FOG to be collected out of the water. The sizing of the Gravity

units are expressed in the gallons it will hold.

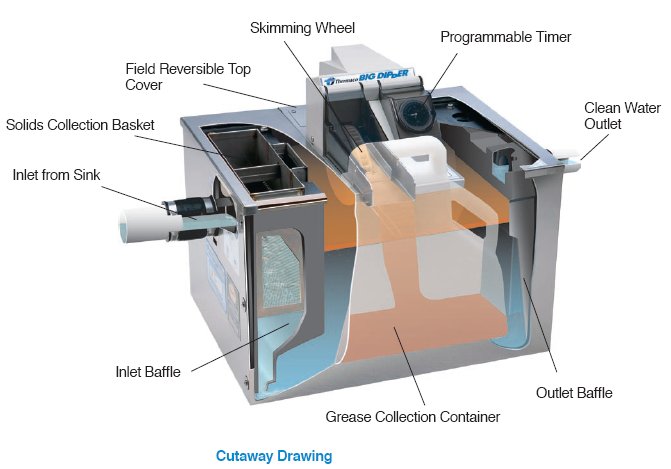

The third is an Automatic Grease Removal Unit (AGRU). This

type of grease trap utilizes mechanical and electrical components to actually

skim FOG out of the water. These systems are smaller yet highly efficient. Most

AGRU units can eliminate 99% of FOG from water. Most have an internal

collection device for food particles, a heating element and a external FOG

collection unit. The AGRUs are more expensive than the the other two, but one

can clearly see that they are lower maintenance and high efficiency. Sizing of

these units varies greatly and can come in sizes small enough to place under a

sink or large enough to accommodate an entire restaurant.

The third is an Automatic Grease Removal Unit (AGRU). This

type of grease trap utilizes mechanical and electrical components to actually

skim FOG out of the water. These systems are smaller yet highly efficient. Most

AGRU units can eliminate 99% of FOG from water. Most have an internal

collection device for food particles, a heating element and a external FOG

collection unit. The AGRUs are more expensive than the the other two, but one

can clearly see that they are lower maintenance and high efficiency. Sizing of

these units varies greatly and can come in sizes small enough to place under a

sink or large enough to accommodate an entire restaurant.

An excellent guide to grease traps is located on PDI's website: PDI's Guide to Grease Interceptors

To read more about the history of grease traps,

click here:Grease Trap 101: History.

To read more about the sizing of grease traps, click here: Grease Trap 101: Sizing.