Grease trap information and sizing guide

Basically, you need to keep two categories in mind as you decide on a grease trap. The first is the local plumbing code/municipal ordinances, and the second is the grease production rate in your restaurant.

So you have read our blog on the importance of grease traps in your restaurant and you are now convinced that you need to invest in a reliable grease trap for your food service establishment (FSE). However, you might still be a bit unsure about how to determine the grease trap application that best fits your restaurant. Trust us when we say that you have nothing to worry about; our aim is to make your selection process easy. By the time you finish reading this blog, you should be able to pick-out an appropriately sized grease trap for your restaurant.

Too Long; Didn't Read

Basically, you need to keep two categories in mind as you decide on a grease trap. The first is the local plumbing code/municipal ordinances, and the second is the grease production rate in your restaurant.

Concerning the first category, you must check whether your state, or local jurisdiction prescribes a grease trap size for your restaurant. If they do, then you definitely want to get a grease trap that at the least meets this standard. Your local jurisdiction will more than likely adopt the Uniform Plumbing Code (UPC) to determine the grease trap needed in your restaurant.

We have simplified the code (UPC) in the blog below. Follow the steps under SECTION A, BULLET 2 - Sizing using fixture capacity - of the blog to determine the size of the grease trap needed in your restaurant by law. The section underlines how you can choose a grease trap based on the size of the compartment sinks that you plan to feed into the grease trap.

Note however that the state prescription does not account for the grease production rate in your restaurant. This is why you also need to consider the second category. The second category is especially necessary when your local jurisdiction does not prescribe a code requirement for your grease trap.

The second category is tailor-made to meet the specific needs of your restaurant. Essentially, you need to consider how much grease waste your restaurant produces. This can be done by following the example in SECTION B of the blog. That section details how you can choose a grease trap based on your restaurant type, number of customers, and the desired maintenance cycle of the grease trap.

Once you have determined the requirement of your local government as well as your restaurant’s grease production rate, you can now compare the recommended grease trap from both categories. For example, if the municipal ordinance on grease traps in your state prescribes a 40 lb grease trap, and your grease production rate calculations show that you need a 50 lb grease trap, then you would need to get a 50 lb grease trap to meet both the state prescribed requirement and the particular need of your restaurant.

The same would apply if the state required grease trap size were 60 lbs and the grease production from your restaurant only warrants a 35 lb grease trap. You would be required by law to buy a 60 lb grease trap and this grease trap would cover the particular grease production needs of your restaurant.

Consult the entire guide below for more detailed information on the selection process. See also the grease trap selection checklist after the guide for a printable bulleted list of steps required for the grease trap selection process.

The Complete Guide

to Grease Trap

Sizing

Sorting through the mess

Many factors go into the choice of a grease trap, and careful attention must be given to these factors in the selection process. The factors include flow rate, liquid volume, waste pipe diameter, volume of fixtures draining, grease production rate, and the determined fixture units. For simplicity's sake, these factors can be lumped into two broader categories - local plumbing codes and grease production rate.

Some erroneously size their grease traps based on one of the two factors listed above, but any methodology that deals only with one of these factors without consideration for the other is not a well-rounded approach. The methodology adopted in this blog is thoroughly informed by the reality that not all FSEs are created equally.

The amount of grease produced daily by any FSE is directly related to the type of food provided at the restaurant. Which is to say that one would not expect the same grease production in a sandwich shop as one would expect in a fried chicken eatery. So then, the sizing of your grease trap must be based not just on the flow rate you expect to experience in the restaurant, but also on the grease production of your restaurant. Note that the average number of customers and the maintenance cycle also play a significant role in the grease production capacity.

The best method will therefore account not just for the local plumbing codes, but also for the grease production rate. It is worthwhile at this point to note that bigger is not always better when it comes to grease trap sizing. Bigger units pose problems of access, pump-out cost, corrosion resistance, larger footprint and build up of hydrogen sulfide (H2S) gases - exposure to high concentrations of H2S can quickly lead to death.

The following sections will address the two sub-categories listed above - local plumbing code and grease production rate.

SECTION A - LOCAL PLUMBING CODE

We start with this header because your aim at the bare minimum must be to meet the required standards of the approved codes for public health and safety.

Your local administrative authorities will point the engineer/plumber setting up your grease trap to one of two options from the Uniform Plumbing Code (UPC), a model code developed by the International Association of Plumbing and Mechanical Officials (IAPMO) to govern the installation and inspection of plumbing systems.

The two options are:

- Gravity flow rates

- Fixture capacity

NOTE: If the two options above are not required in your local jurisdiction (this is highly unlikely), then you can disregard what follows and charge right ahead to the grease production rate section further below.

1. SIZING USING GRAVITY FLOW RATES

Under this method, the grease trap is sized according to the diameter of the grease waste pipe. The diameter of the pipe determines its maximum flow rate. So, as you’ll see in Table 1 below, a 2” waste diameter pipe has a maximum flow rate of 20 gpm. The code suggests a grease trap size based on this flow rate in accordance with the desired drainage period as seen in the table below.

If you choose a two-minute drainage period, for a 2” pipe you would need a grease trap rated for 10 gpm. The UPC code also states that the total capacity in gallons of fixtures discharging into this particular grease trap (10 gpm) must not exceed two and one-half times the certified flow rate (gpm) of the grease trap. Essentially, for this particular example, you must make sure that the volume of the fixtures feeding into the 10 gpm grease trap do not exceed 25 gallons (i.e., 2.5 x 10). Please note that the term “fixture” refers to each appliance or equipment to be connected to or discharged into a grease trap.

Table - 1. Grease trap sizing using gravity flow rates

| DIAMETER OF GREASE WASTE PIPE (inches) | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|

| MAXIMUM FULL PIPE FLOW (gpm)1 | 20 | 60 | 125 | 230 | 375 |

| ONE-MINUTE DRAINAGE PERIOD (gpm) | 20 | 75 | 150 | 250 | 500 |

| TWO-MINUTE DRAINAGE PERIOD (gpm) | 10 | 35 | 75 | 125 | 250 |

1 ¼ inch slope per foot (20.8 mm/m).

> QUICK NOTE ON THE DRAINAGE PERIOD

There usually is some confusion about whether to use the One-Minute Drainage Period or the Two-Minute Drainage Period.

Under normal conditions the Two-Minute Drainage Period should be your choice because it most accurately reflects the designed flow rates of your piping system. This designed flow rate accounts for a “half-full” capacity in your pipes. The pipes in reference here are those exiting your FSE.

The Two-Minute Drainage Period is also a reasonable choice when you consider the size of the tail-piece or pipe directly below your compartment sinks. It typically takes longer than 1 minute to empty out a sizeable compartment sink, especially when one considers that most compartment sinks use a 1.5" - 2" tail piece. Consequently, the Two-Minute Drainage Period would be a proper option.

However, real life is not that black and white, and nothing ever works the way it is designed to work...okay maybe that’s an overgeneralization, but you get the point. The One-Minute Drainage Period assumes a faster drain period which correlates to a relatively bigger grease trap. The Two-Minute Drainage Period assumes a slower drain period which correlates to a relatively smaller grease trap. Reality is perhaps somewhere between the two options and as such, you would be better off choosing the One-Minute Drainage Period since it is the most conservative option.

2. SIZING USING FIXTURE CAPACITY

The second method is based on fixture capacity. Adopt this method if the fixture dimensions in your FSE are all known. There is a correlation between the volume of the fixtures and the maximum flow rate to the grease trap. Grease traps are typically rated based on flow rates, so if you can calculate the total volume of the fixtures feeding the grease trap, you can determine the size of the grease trap.

See the steps below to calculate the flow rate:

- Calculate the volume of the fixture your grease trap is servicing.

- Measure the length of the fixture - (L) (inches)

- Measure the depth of the fixture - (D) (inches)

- Measure the width of the fixture - (W) (inches)

- Multiply all three values above to determine the volume (L x D x W) - we’ll call this value : (A), with units in “cubic inches.” (A) cubic inches.

- Convert the volumetric unit in cubic inches to gallons.

Note: 1 gallon = 231 cubic inches

- Simply divide the value for (A) above by 231. This will give you the volume in gallons. (B) gallons.

- Multiply the volume in gallons by the fill factor.

- Determine the fill factor

- Also known as the "loading factor," this value refers to the fill capacity of your sink. If you typically fill your sink up to approximately 75 percent of its "full" capacity, then your fill factor is 0.75.

- (B) gallons x 0.75 (fill factor) = (C) gallons.

- Determine the fill factor

- Determine the drainage period. Note: The drainage

period is the time it takes to completely drain the fixture/sink

- The drainage period will either be 1 minute or 2 minutes. Generally, one minute drainage periods are optimal, but in some cases two minute drainage periods are acceptable - see note above on drainage period.

- Divide (C) either by 1 minute or 2 minutes pending the decision made in the sub-bullet above.

- (C)/1 minute = (D) gallons per minute (gpm)

- You should now have the expected flow rate of your set-up. See the example under Table 2 for a working example of the process.

NOTE: You must account for all other fixtures that you intend to connect to the grease trap. See the table below for more information on how to account for other fixtures in your calculations.

Table - 2. Total load from all fixtures that discharge into the grease trap

| FIXTURES | Compartment size | 24 inches x 24 inches x 12 inches | Additional fixture 1 | Additional fixture 2 | - |

|---|---|---|---|---|---|

| COMPARTMENTS | - | 2 | - | - | - |

| Load (gallons) | - | 44.9 | 3 | 2 | 49.9 |

| SIZE OF GREASE INTERCEPTOR ONE-MINUTE DRAINAGE (gpm) | - | 44.9 | 3 | 2 | 50 |

| TWO-MINUTE DRAINAGE PERIOD (gpm) | - | 22.5 | 1.5 | 1 | 25 |

Note that the “load” value is calculated using the steps 1 through 5 listed above. The steps are simplified below:

- A = 24 x 24 x 12 = 6912 cubic inches

-

B = 6912/231 = 29.9 gallons

- NOTE - For two compartments, B = 29.9 x 2 = 59.8 gallons

- C = 59.8 x 0.75 = 44.9 gallons

- D = 44.9/1 for a drainage period of 1 minute = 44.9 gallons per minute (gpm)

If you only had two 24 inch x 24 inch x 12 inch sink compartments, you would be required to buy a grease trap capable of handling 45 gpm (or 23 gpm for the 2 minute drain period).

However, if you have other fixtures feeding into the grease trap, as the table above shows, then you will have to determine the load capacity of each fixture.

The example above in Table 2 has two extra fixtures with a total load capacity of 5 gallons (2 gallons + 3 gallons). The size of the grease trap for the application here would then be determined by adding 44.9 gallons to 5 gallons. Summing up to a total of approximately 50 gallons. The applicable grease trap for a one minute drain period will then be a 50 gpm grease trap, and 25 gpm for a two minute drain period.

This same process has been applied to Atlantic Metalworks’ (AMW) Economy compartment sinks.

NOTE: Any additional fixtures will require a re-calculation of the sizing of your grease trap. The calculations below in Table 3 only reflect the sizing for the equipment listed.

Use the table below to help size your AMW Grease traps according to the type and number of compartment sinks serviced. Do not install a smaller AMW unit than the one suggested and rated below in Table 3. Remember that the table below is at best a suggestion, consult a licensed plumber regarding your specific requirements.

Table - 3. Grease trap sizing for AMW compartment sinks

| SKU | 1CS-101410-2 | 1CS-242414-2 | 1CS-162012-2 | 1CS-101410-0 | 1CS-242414-1 | 1CS-242414-0 | 1CS-181812-0 | 1CS-162012-1 | 1CS-162012-0 | 1CS-181812-2 | 1CS-181812-1 | 2CS-162012-2 | 2CS-162012-1 | 2CS-162012-0 | 2CS-181812-0 | 2CS-101410-2 | 2CS-101410-0 | 2CS-242414-2 | 2CS-242414-0 | 2CS-181812-2 | 3CS-151512-2 | 3CS-181812-1 | 3CS-162012-1 | 3CS-242414-0 | 3CS-181812-0 | 3CS-101410-0 | 3CS-101410-1 | 3CS-101410-2 | 3CS-242414-2 | 3CS-162012-0 | 3CS-162012-2 | 3CS-181812-2 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compartments | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| Dimensions (inches) | 10*14*10 | 24*24*14 | 16*20*12 | 10*14*10 | 24*24*14 | 24*24*14 | 18*18*12 | 16*20*12 | 16*20*12 | 18*18*12 | 18*18*12 | 16*20*12 | 16*20*12 | 16*20*12 | 18*18*12 | 10*14*10 | 10*14*10 | 24*24*14 | 24*24*14 | 18*18*12 | 15*15*12 | 18*18*12 | 16*20*12 | 24*24*14 | 18*18*12 | 10*14*10 | 10*14*10 | 10*14*10 | 24*24*14 | 16*20*12 | 16*20*12 | 18*18*12 |

| 2 Min. Drain (gpm) | 8 | 14 | 8 | 8 | 14 | 14 | 8 | 8 | 8 | 8 | 8 | 14 | 14 | 14 | 14 | 8 | 8 | 30 | 30 | 14 | 14 | 20 | 20 | 40 | 20 | 8 | 8 | 8 | 40 | 20 | 20 | 20 |

| 1 Min. Drain (gpm) | 8 | 30 | 14 | 8 | 30 | 30 | 14 | 14 | 14 | 14 | 14 | 30 | 30 | 30 | 30 | 14 | 14 | 70 | 70 | 30 | 30 | 40 | 40 | 100 | 40 | 14 | 14 | 14 | 100 | 40 | 40 | 40 |

NOTE - Number of compartments was considered in the calculations and 0.75 was used as the fill factor.

Now, the main discussion thus far in this blog has based sizing on the flow rate of the fixtures that you intend to connect to your grease trap. However, as mentioned earlier, this method is incomplete due to variants like grease production rate, number of customers and the maintenance cycle prescribed by your local jurisdiction.

A savvy restaurant owner like you knows that meeting the local regulatory requirements in your FSE is just the first step to an efficient work environment. The following section covers the next steps needed to ensure that you size your grease trap based on the particular needs of your restaurant.

SECTION B - GREASE PRODUCTION RATE

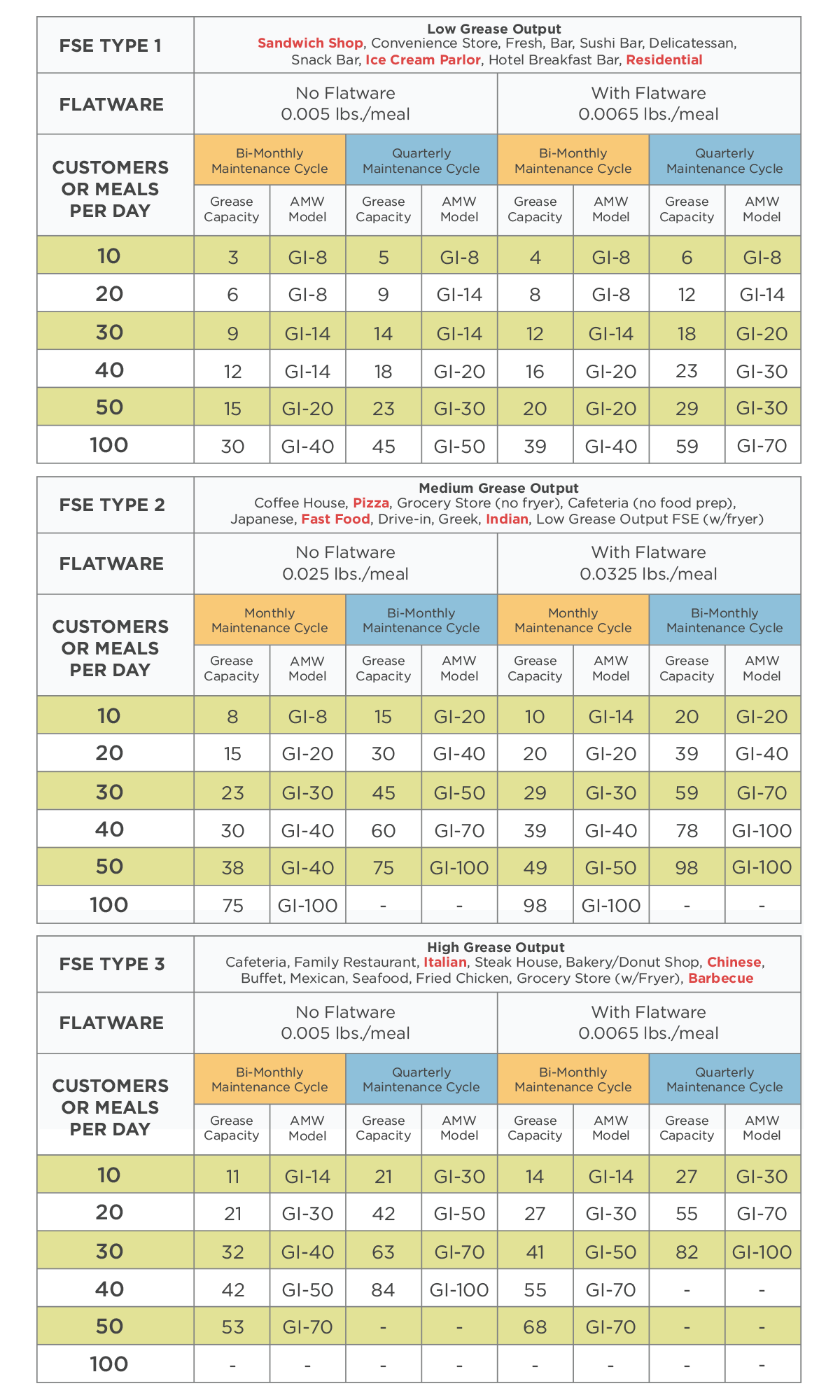

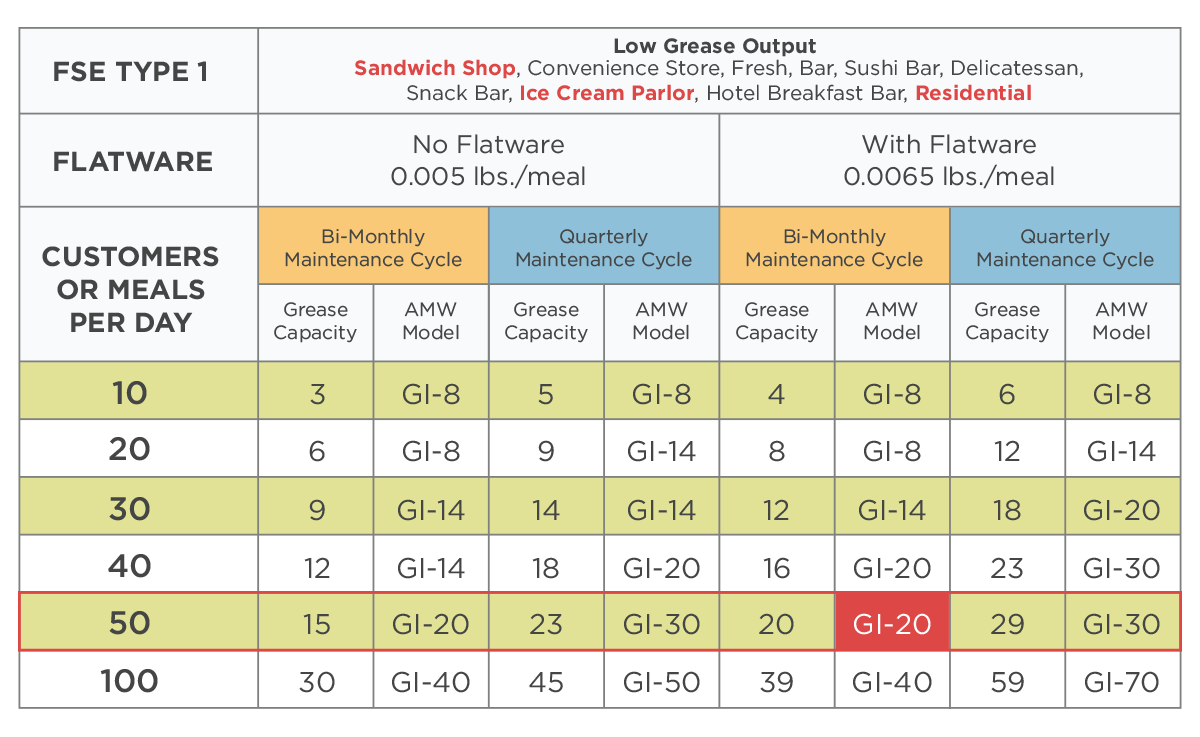

The grease production capacity of your restaurant is the biggest determining factor in your choice of a grease trap. As mentioned above, a sandwich shop does not need the same grease trap application as does an Italian restaurant. The table below accounts for both the grease production capacity based on your type of FSE and the maintenance cycle of your grease trap. See the "How To Use The Table" section immediately below the table.

Table - 4. Grease output and corresponding AMW grease trap

*This table was adapted from Schier Products Company’s guide on grease trap sizing - the Grease production values are based on actual data obtained from the study of 20 restaurants monitored over a 9 month period by municipal pretreatment officials, pumper contractors, and two independent research reports. Actual grease production is independent to every restaurant and will vary by menu type and kitchen practices.

HOW TO USE THE TABLE

Do not panic, yes this was supposed to be easy, and it really is! The table above is very easy to follow. See the steps below:

ASSUME THIS IS YOUR CURRENT SITUATION:

- You own a sandwich shop where you serve your customers with flatware.

- You typically average 50 customers/meals per day.

- You run a tight ship with few employees and therefore prefer to clean out your grease trap every two months. (Bi-monthly maintenance cycle).

HOW DO YOU SELECT YOUR GREASE TRAP?

- Find the FSE (Food Service Establishment) rows in the table and notice from the rows that different types of FSEs are listed.

- Scan through the three rows to find the FSE most similar to yours. From our “current situation” example above, the sandwich shop belongs under the FSE TYPE 1 row. This is the LOW GREASE OUTPUT category.

- Since the sandwich shop serves with flatware, find the "With Flatware" row right under the LOW GREASE OUTPUT row.

- Now find the maintenance cycle on the table in relation to the number of customers or meals you serve per day.

- Your grease trap size should be the Atlantic Metal Works (AMW) GI-20.

As you can tell, the grease trap needed for your particular FSE, (AMW GI-20), which is rated at 20 gpm, is lower in rating when compared to the calculated code requirement of 45 gpm for two 24 inch x 24 inch x 12 inch sink compartments. Since you are required by law to meet the code standards, you would then select the grease trap closest in rating to 45 gpm - the AMW GI-50.

However, this will not always be the case. If your FSE is a high grease output facility, with the other factors in your restaurant remaining constant (excluding the maintenance cycle which is set at a minimum of 1 month), you would need the AMW GI-70 for the same two 24 inch x 24 inch x 12 inch sink compartment application.

So then, both methods must be used hand in hand as you strive to have the most efficient restaurant.

CONCLUDING REMARKS

Thank you for reading our blog. As stated at the onset, the aim was to make the complicated and messy world of grease trap selection simple - hopefully we have been successful in doing just that. Remember that there are two main categories that you need to consider before selecting your grease trap. The local plumbing codes and the grease production rate. Since the plumbing codes do not account for grease production (i.e FOG loading), due diligence means taking the necessary steps to size your grease trap based on the particular needs of your FSE.

SIZING CHECKLIST

- Checklist on the municipal ordinances on the grease trap size required

of your FSE

- Check the local plumbing requirement for your grease trap

- Select sizing method

- Size using gravity flow rates or

- Size using fixture capacity

- Determine and record recommended grease trap size

- Checklist on the grease trap selection based on grease production rate

- Determine the grease production capacity of your FSE

- Record FSE type

- Determine FSE type from Table 4 (i.e FSE Type 1, 2 or 3)

- Select Maintenance Cycle

- Estimate the number of customers per day

- Determine and record recommended AMW grease trap

- Determine the grease production capacity of your FSE

- Compare recommended grease trap from both methods.

- Select the grease trap with the higher rating of the two recommendations