Grease Trap 101: Sizing

Even more important than the type of grease trap you need is the size of grease trap you need. If you have a grease trap which is too small, then either you'll be cleaning it everyday or your grease trap will be allowing FOG through into the sewage system.

Even more important than the type of grease trap you need is the size of grease trap you need. If you have a grease trap which is too small, then either you'll be cleaning it everyday or your grease trap will be allowing FOG through into the sewage system. If your grease trap is too large, then you'll spend more money than you need to, get longer detention rates and get into the bad habit of not regularly cleaning it (because you've got extra space, why clean it more often?).

There are three methods of sizing a grease trap.

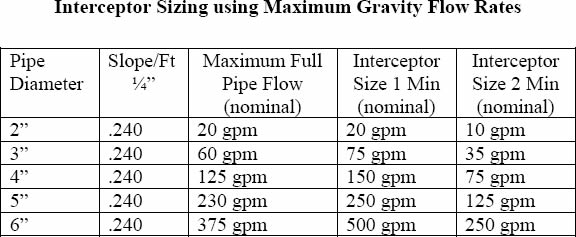

The first is sizing according to your Waste Pipe Diameter. For pipes installed at a standard slope of 1/4"/foot, water will flow at a maximum rate on its own thanks to gravity. Based on this, a grease trap can be determined since flow controls are typically required to be installed with the grease trap.

The second method is sizing based on the total volume of fixtures draining.

To use this method, you need to figure out the total volume draining from all fixtures (going through the grease trap) in a period of one minute plus the total of other fixtures which have a determined drain rate. This will produce the total flow rate for the facility and allow you to determine the GPM of the grease trap.

Here is an example: Suppose you had a 18 x 18 x 12 single compartment sink going into your grease trap...

- Determine the volume of the fixture by multiplying the length by height by width.

- 18 x 18 x 12 volume is 3,888 cubic inches.

- Determine the capacity in gallons (1 gallon = 231 cubic inches )

- 3,888 divided by 231 is 16.83 gallons

- Determine the drainage load. Normally, you would fill a sink to 75% capacity.

- 75% of 16.83 is 12.62 gallons.

- Next determine flow rate and drainage period. Generally, one minute drainage periods are optimal, but in some cases two minute periods are acceptable. Flow rate = Actual Drainage divided by Drainage period.

- 12.62 = actual drainage, one minute drainage period = 12.62 gpm flow rate. 12.62 with a two minute flow would produce a 6.31 gpm flow rate.,

- This Flow rate will give you an idea of what interceptor to choose. A 12.62 gpm flow rate would dictate purchasing a grease trap (slightly larger than the flow rate) of perhaps 15 gpm or 20 gpm depending on the vendor's options. Prima-Restaurant-Equipment has both 15 GPM (GI-30) and 20 GPM (GI-40) Grease Traps.

-

The third standard sizing method is based upon determined drainage fixture units (DFU).

Each fixture in the facility has a drainage fixture unit. This unit is assigned by the plumbing code and uses an average flow rate for that fixture. Sizing to the peak rates on all your fixtures will give you a good sized grease trap but may cause peak flow rate problems and cause a delay in flow. This is not a problem with a Hydromechanical Grease trap.

PDI asks the questions, "Is bigger better?" The answer is not always. PDI cautions that over sizing can result in the deterioration of your plumbing, interceptor and drainage system so proper sizing is a critical issue.

Lots of resources are available online to help you decide which size of grease trap to buy. PDI has a great resource here. For a good sizing worksheet using the Uniform Plumbing Code go here.

As always, please consult with your local health inspector to determine the proper sizing method and proper size for your local facility.

To read more about the history of grease traps, click here: Grease Trap 101: History.

To read more about the types of grease traps, click here: Grease Trap 101: Types.